A brief introduction to the fascinating history of beer—such a broad and nuanced topic cannot be covered in just a few lines. From its ancient origins to its modern evolution, the history of beer is a complex story filled with innovation and tradition. For those interested in diving deeper into this subject, we recommend exploring a selection of books available on Amazon that will provide a more detailed and complete view of the rich history and cultural impact of this special beverage.

You can still find a brief introduction to the history, emphasizing the beer de-alcoholization process, along with some interesting facts.

History of Beer and the Development of Non-Alcoholic Beers

Ancient Origins

The history of beer dates back to ancient times, with evidence of its production in Mesopotamia around 3500 BC. The first beers were made from barley and other fermented grains. The Sumerians, Egyptians, and other ancient civilizations had already developed rudimentary brewing methods, valuing both the taste and the nutritional properties of beer.

The oldest known beer is approximately 7,000 years old. Remnants of an ancient beer recipe were found at the archaeological site of Godin Tepe in Iran, dating back to around 5,000 BC.

In ancient Egypt, beer was a fundamental beverage and considered a gift from the gods. Egyptians of all ages, including children, consumed beer daily, and it was also used in religious offerings. Workers who built the pyramids received beer rations as part of their wages.

Evolution in Europe

During the Middle Ages, beer production was refined in European monasteries, where monks developed fermentation techniques and added hops, which helped to stabilize and preserve the beer. Over time, beer became a popular drink throughout Europe, with its flavor and style varying by region.

In 1516, Germany implemented the Beer Purity Law (Reinheitsgebot), which stipulated that beer could only contain water, barley, hops, and yeast. This law was designed to ensure the quality and purity of beer, and it continues to influence brewing practices in Germany to this day.

Industrial Revolution and Modernization

The Industrial Revolution in the 19th century brought significant advances in brewing. The invention of pasteurization by Louis Pasteur in 1864 allowed beer to be preserved for longer periods and produced in larger quantities. Additionally, the introduction of refrigeration and improvements in fermentation processes led to the development of cleaner, more stable lagers.

In 2015, a specially designed beer was taken into space. The Japanese brewery Sapporo created a beer to be consumed in microgravity during the International Space Station (ISS) mission, marking a milestone in beer history.

The Development of Non-Alcoholic Beers

- Vacuum Distillation Method: Involves heating beer at low pressure to evaporate alcohol at lower temperatures, minimizing flavor loss.

- Interrupted Fermentation Method: Fermentation is halted before a significant amount of alcohol is produced, using special yeasts or techniques to stop fermentation prematurely.

The concept of non-alcoholic beer began to develop in the late 20th century. The first attempts to produce non-alcoholic beer were made in the 1970s, but it was in the 1980s when production techniques were perfected. Brewing non-alcoholic beer is based on two main methods:

The first patent for non-alcoholic beer was registered in 1919, right after Prohibition in the United States. During this period, producing non-alcoholic beer became a way to circumvent the restrictions placed on alcohol.

Recent Growth and Popularity

In recent decades, the demand for non-alcoholic beer has grown considerably due to a greater focus on health and well-being, as well as increasing concerns about alcohol consumption. Brands have perfected recipes and techniques to offer non-alcoholic beers that maintain the flavor and quality of traditional beers.

Today, non-alcoholic beer offerings include a wide range of styles and flavors, allowing consumers to enjoy a rich and varied beer experience without the effects of alcohol. Continued innovation in the industry ensures that these beers will keep evolving and improving.

Steps in the Production and Brewing of Non-Alcoholic Beer

The brewing process is a complex topic involving a series of stages and techniques. From selecting ingredients to fermentation and bottling, each step is crucial to creating the beer we enjoy. For a deeper understanding of this fascinating process, we recommend exploring specialized books available on Amazon that offer a detailed and complete view of beer brewing.

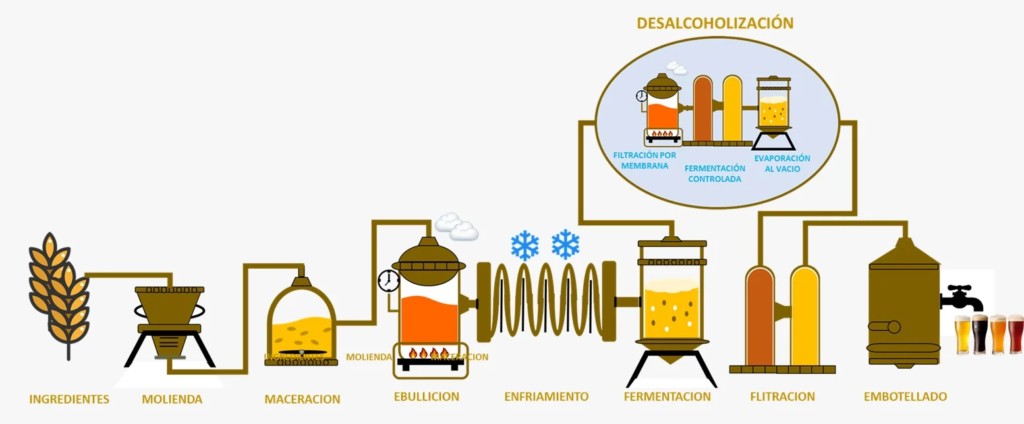

Below is a description of the main steps and tools used to produce beer, including the alcohol removal step.

In the same way you can find a detail explanation on how to cook beer at home easily

Summarized Steps for Beer Production

- Ingredient Selection

- Basic Ingredients: Water, malt (barley or wheat), hops, and yeast.

- Malt: Preferably of high quality to ensure good flavor and aroma.

- Milling

- The malt is milled to break the grains and facilitate the extraction of fermentable sugars.

- Mashing

- The milled malt is mixed with hot water in a process called mashing.

- Objective: To convert the starches in the malt into fermentable sugars.

- Filtration

- The resulting wort from the mashing is filtered to separate the solids (grains).

- Boiling

- The filtered wort is boiled, and hops are added.

- Objective: To sterilize the wort and extract bitter and aromatic compounds from the hops.

- Cooling

- The hot wort is rapidly cooled to fermentation temperature.

- Fermentation

- The cooled wort is transferred to a fermentation tank, and yeast is added.

- Natural Process: The yeast converts the sugars into alcohol and CO₂.

- For non-alcoholic beer, the process is stopped before significant alcohol is produced.

- De-alcoholization

- Common Methods:

- Vacuum Evaporation: The wort is heated at a low temperature to remove alcohol.

- Membrane Filtration: A membrane is used to separate the alcohol from the wort.

- Controlled Fermentation: The amount of sugar available to the yeast is limited.

- Common Methods:

- Aroma Recovery

- During de-alcoholization, aromatic components lost are recovered and re-incorporated to maintain flavor.

- Carbonation

- CO₂ is added to carbonate the beer, giving it effervescence.

- Final Filtration

- The beer is filtered to remove any residual particles and achieve a clear product.

- Bottling and Packaging

- The non-alcoholic beer is packaged in bottles, cans, or kegs.

- Quality Control: Each batch is tested to ensure it meets flavor and quality standards.

- Distribution The packaged beer is distributed to points of sale for consumption.

These steps ensure the production of a non-alcoholic beer that retains the desired flavor and characteristics, offering a refreshing alternative without the alcoholic effects.